Stainless Steel Restoration

What is stainless Steel?

The class of steels (alloys) that contain the common element of chromium is called stainless steel. The chromium must exist at a level of at least 10.5% for the steel to be called stainless steel. There might be other elements present in the steel, such as nickel. However, it’s the chromium that gives stainless steel the great corrosion-resistant properties. It’s the chromium that reacts positively with oxygen creating a renewable protective layer of chromium oxide.

Stainless steel is good for the environment – it’s fully recyclable

The most common grades of stainless steel are 304 and 316. 316 is marine grade stainless steel. When you see exterior architectural fittings like railings, light fixtures and balustrades, those are commonly made from 316-grade stainless steel. When it’s close to marine environments, molybdenum is added to give 316-grade steel the added corrosion protection it needs. The stainless steel used in sinks, kitchen preparation areas, barbecues and work surfaces is usually 304-grade stainless steel and does not have molybdenum added.

Can stainless steel corrode?

Though it’s more resistant to corrosion than regular carbon or alloy steels, stainless steel can corrode in some circumstances. It’s called “stainless” not “stainFREE”. When it corrodes, however, it doesn’t corrode the way unprotected carbon steel corrodes, when it forms layers of red flaking rust when it’s exposed to moisture and air. The rust (or iron oxide film) is an active component and accelerates corrosion by creating more iron oxide. Fortunately, stainless steel contains enough chromium to form a passive film of chromium oxide; this prevents additional surface corrosion. It also blocks the corrosion from spreading into the internal structure of the metal. The cause of corrosion in stainless steel is mostly damage to the chromium layer and contaminants becoming lodged on the surface of the stainless steel. Regular maintenance can help to stop corrosion forming on the surface.

What’s the best way to maintain stainless steel?

Interior stainless (such as sinks, appliances, etc.) – Use gentle care. If you use a soft cloth to wash and wipe the stainless, most fingerprints and surface makes will lift off easily. Dry the surface thoroughly with another soft cloth. If marks remain, you can repeat the procedure above, but use a mild detergent as well. If marks still remain, you can use a diluted cream cleanser. Don’t use a circular wiping motion or rub against the grain of the stainless steel because some detergent or cleanser residue can become trapped and scratch the stainless.

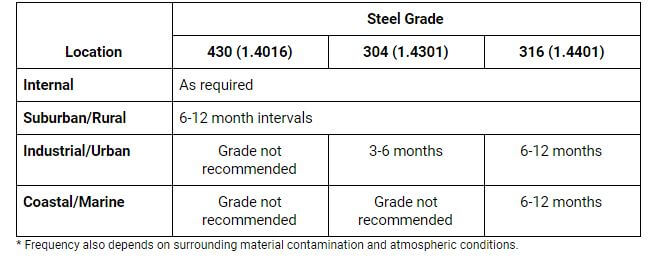

Exterior (marine fittings, architectural fittings, etc.) – Use fresh water for regular cleanings. If you clean stainless steel used in these applications this way, you can help to prevent the buildup of salt and environmental contaminants.

Impact Metal Fabrication are experts in the restoration of Stainless Steel, Aluminium and Brass for residential, commercial or marine applications. We can offer the best solutions for removing scratches, dents and tea stains to have your stainless-steel looking like new! Based at Tuggerah, we currently service the Central Coast, Sydney & Newcastle/Hunter regions.

We specialise in lift interiors and door frames, kitchens, cafés and can also restore stainless steel handrails and balustrading.

Services we offer include

- Clean & polish – using Suhner INOX, we can make your stainless-steel shine as new!

- Linishing – removal of scratches & blending of small dents using our barrel grinders, before finishing with a polish to bring back that shine

- Weld cleaning – removal of tea stains from the welds

- Customised maintenance programs – we can design a tailor-made preventative maintenance program to specifically suit your needs. Regular maintenance on your stainless-steel surfaces will prolong the life of the metal

- Replacement of damaged stainless – if the damage is too severe to be repaired, we can also fabricate and install replacement stainless-steel, aluminium or copper panels using our fully equipped workshop at Tuggerah

Contact us now for a free quote and honest advice.